Replacement gaskets into a snack food manufacturing factory. Designed to help reduce the level of product contamination and waste.

View Case Study

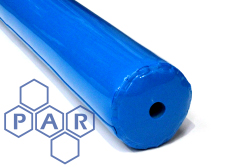

Metal detectable TPU roller sleeves. Designed to cover sponge or foam rollers to prevent contamination from deteriorating material.

View Case Study

PVC polyester covers incorporating clear PVC windows. Protecting expensive control panels during wash down periods.

View Case Study

PVC polyester covers incorporating clear PVC windows. Used to protect expensive label printing panels during wash down periods.

View Case Study

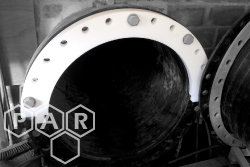

A bespoke manufactured, machined plastic tapered gasket supplied in two halves. Designed to seal between misaligned pipe flanges.

View Case Study

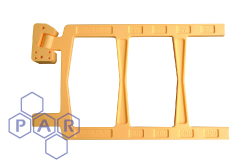

Plastic machined then fabricated components. Designed as replacements for heavy steel units for ease of use and maneuverability.

View Case Study

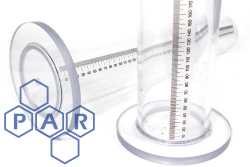

Watertight, clear plastic settlement tubes. Part of a kit from OEM suppliers, PAR manufactured and supplied as an individual unit.

View Case Study

Bespoke plastic fabricated parts to replace exisiting units. Design improvements were made to add new functions to the old design.

View Case Study

Hand cut and stitched pipe and valve insulation jackets. Designed to insulate cold pipes to reduce the risk of bursting and reduced flow.

View Case Study

A flexible, welded TPU chute used in a snack food bagging application. Designed to replace rigid plastic variants that can easily crack.

View Case Study

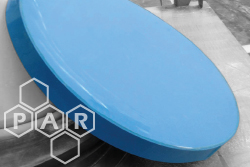

Flexible, durable and food contact approved. Designed to replace old stainless steel lids which no longer fit due to the dented IBC openings.

View Case Study

Portable containment units for a leading water authority. Designed to safeguard personnel from chemical exposure.

View Case Study

Self-closing industrial safety gates to the powder processing industry. Designed to protect personnel from accidental falls.

View Case Study

Plastic engineered polypropylene tank cover manufactured for a leading water authority. Designed to protect pipework against freezing.

View Case Study

Utilising in-house CNC technology, we created a new set of clear Polycarbonate panels providing significant cost savings.

View Case Study

Replacement sludge weir plates were machined in-house. Downtime was minimal, ensuring the thickener was operational on the same day.

View Case Study